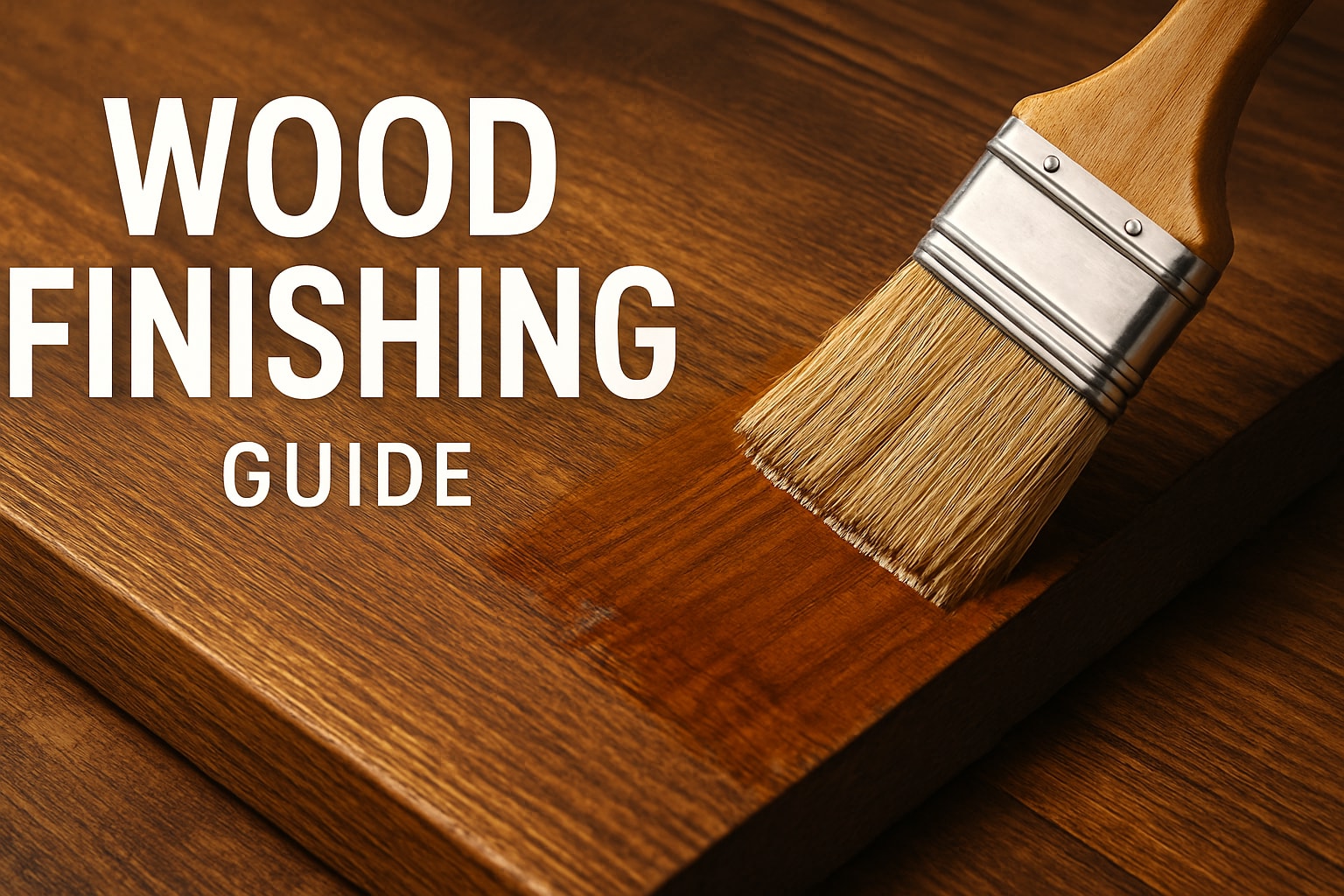

Woodworking and custom furniture are making a vibrant comeback in 2026 as more homeowners seek one-of-a-kind pieces with exceptional durability. Choosing the right wood finishing is essential, not only for enhancing the natural beauty of your furniture, but also for preserving its value and lifespan.

With the right techniques, wood finishing can transform ordinary surfaces into works of art. This guide delivers expert advice, up-to-date methods, and professional secrets to help you achieve flawless, lasting results.

Discover the latest trends, step-by-step finishing processes, essential tools, recommended products, and solutions for advanced finishing challenges.

Understanding Wood Finishing: Trends and Fundamentals for 2026

Wood finishing plays a vital role in preserving, beautifying, and increasing the value of furniture and interior woodwork. As the demand for custom pieces continues to rise in 2026, understanding wood finishing fundamentals and trends is crucial for both DIYers and professionals.

The Purpose and Benefits of Wood Finishing

A proper wood finishing process safeguards wood against moisture, daily wear, and UV exposure. It also highlights the unique grain and color, bringing out the character of each piece. This enhancement not only elevates the visual appeal but also extends the lifespan and resale value of furniture.

Did you know that over 70% of high-end furniture buyers in 2025 identified finish quality as a top purchasing factor? This emphasizes how crucial wood finishing is for anyone aiming to create lasting, valuable pieces.

Key Types of Wood Finishes in 2026

In 2026, wood finishing offers a variety of options, including oil-based, water-based, hybrid, and eco-friendly finishes. Each type differs in durability, appearance, and maintenance needs.

| Finish Type | Durability | Appearance | Maintenance | Eco Rating |

|---|---|---|---|---|

| Oil-based | High | Rich, warm | Moderate | Low |

| Water-based | Moderate | Clear, natural | Easy | High |

| Hybrid | High | Versatile | Moderate | Moderate |

| Eco-friendly | Moderate | Subtle, matte | Easy | Very High |

Innovations like low-VOC and bio-based finishes are making wood finishing safer and more sustainable for users and the environment.

Popular Wood Finishing Trends

Modern interiors in 2026 favor matte and ultra-matte finishes for a clean, contemporary look. The natural "naked wood" effect is achieved with advanced sealers that protect without altering color. Creative layering and color-tinted finishes are also on the rise, offering new ways to personalize projects. For example, Scandinavian-inspired bleached wood is increasingly popular, reflecting the global taste for airy, minimalist spaces.

For further inspiration and current design ideas, explore these Interior wood finishing ideas.

Wood Species and Finish Compatibility

Not all woods react the same to wood finishing products. Hardwoods and softwoods absorb finishes differently, sometimes resulting in blotchy or uneven effects. Exotic woods may require special preparation to ensure smooth, consistent results.

A 2025 survey found that 60% of DIYers faced challenges with blotchy finishes, especially on softwoods. Choosing the right wood finishing method for the species at hand is key to professional results.

Environmental and Health Considerations

With VOC regulations tightening in North America and Europe, the wood finishing industry is shifting towards plant-based and non-toxic products. Safe application and disposal are now standard practices, protecting both the user and the environment.

Always ensure proper ventilation and use personal protective equipment when working with wood finishing products to minimize exposure to fumes and chemicals.

Essential Tools and Safety Gear for 2026

Having the right tools is essential for effective wood finishing. In 2026, HVLP sprayers, microfiber applicators, and digital moisture meters are standard in professional and hobbyist workshops.

Proper ventilation and PPE, such as respirators and gloves, are mandatory. Many workshops also use smart sensors to monitor air quality, ensuring a safe environment during all stages of wood finishing.

Step-by-Step Wood Finishing Process: From Prep to Perfection

Achieving a flawless wood finishing result is a methodical process that demands attention to every stage. Whether you are restoring a vintage piece or crafting modern furniture, following a precise sequence ensures durability and beauty. Each step, from preparation to final polish, builds on the last, making it essential to approach wood finishing with patience and expertise. For those seeking an in-depth technical foundation, the Finishing of wood resource offers a comprehensive guide to methods and protective benefits.

Step 1: Surface Preparation and Sanding

The foundation of exceptional wood finishing lies in meticulous surface preparation. Begin by inspecting the wood for dents, scratches, or raised grain. Use a sanding sequence, starting with 80-grit for rough surfaces and progressing to 220-grit for a silky finish. This gradual approach removes imperfections and opens the grain for even absorption.

A common pitfall is skipping grits or rushing the process, resulting in visible flaws after finishing. Tack cloths and vacuum systems are invaluable for dust removal, ensuring particles do not mar the final coat. Addressing any surface defects early prevents issues that are difficult to fix later in the wood finishing process.

Proper dust control is essential. Use microfiber cloths and dust extraction systems to maintain a clean workspace. Statistics reveal that 85% of finishing flaws are traced to inadequate preparation, highlighting the importance of this step. Investing time here sets the stage for results that rival professional standards in wood finishing.

Step 2: Conditioning and Stain Application

Conditioning is critical, especially when working with softwoods or blotch-prone species. Apply a wood conditioner before staining to promote uniform absorption and prevent patchy results. This is particularly effective for woods like pine or maple, where uneven color can detract from the finished appearance.

Select the appropriate stain type for your project. Gel stains provide excellent control and minimal dripping, while water-based stains offer fast drying and vibrant hues. Oil-based stains penetrate deeply, enhancing grain definition. Application methods vary: brushes allow for precision, rags offer a hand-rubbed look, and sprayers deliver even coverage on large surfaces.

Achieving consistent color is a hallmark of expert wood finishing. Use pre-stain conditioner on maple to avoid blotchiness, and always test the stain on an inconspicuous area first. Even application, careful timing, and wiping away excess stain lead to stunning results. Remember, each step in the wood finishing journey influences the final outcome.

Step 3: Sealing and Building Finish Layers

Once staining is complete, sealing locks in color and provides a smooth base for subsequent layers. Choose from shellac, sanding sealers, or modern water-based alternatives, depending on the desired finish and wood species. Sealers reduce grain raising and create an even surface for topcoats.

Layering is key in wood finishing. Apply thin, even coats, allowing each to dry fully before sanding lightly with fine-grit paper. This builds depth and enhances protection. Environmental factors like humidity and temperature can affect dry times, so monitor conditions to avoid issues.

Dust removal between coats is crucial. Use a tack cloth or compressed air to clear particles, ensuring the next layer adheres properly. This attention to detail in wood finishing results in a finish that is both durable and visually appealing.

Step 4: Applying Topcoats (Polyurethane, Lacquer, Varnish, Oils)

Selecting the right topcoat is essential for matching the intended use and appearance of your project. Polyurethane offers exceptional durability, making it ideal for high-traffic surfaces such as kitchen tables and flooring. Lacquer dries quickly and provides a high-gloss look, while varnish delivers a classic, warm sheen. Oils, like tung or linseed, enhance natural grain and are favored for a subtle finish.

Application technique matters in wood finishing. Brushing is traditional and offers control, but spraying provides a smoother result on large or detailed pieces. Wiping is best suited for oils, allowing for an even, hand-finished appearance. Consider the pros and cons of waterborne versus solvent-based topcoats, balancing eco-friendliness with performance.

Between coats, always sand lightly and remove dust to maintain clarity and adhesion. This stage in wood finishing defines both the durability and the tactile qualities of the final piece, making careful application essential.

Step 5: Final Curing and Polishing

Curing is the final step, allowing the finish to achieve peak hardness and clarity. Curing times vary: water-based finishes may set within days, while oil-based options can require weeks. UV-cured finishes offer rapid results for those seeking efficiency in wood finishing.

Once cured, polishing elevates the surface to a flawless sheen. Buffing compounds and fine abrasives can be used to achieve the desired gloss level, from satin to high-gloss. Hand rubbing or machine buffing removes minor imperfections and enhances smoothness.

Maintain your finished piece with gentle cleaning and periodic reapplication of protective products. Proper curing and polishing not only enhance appearance but also extend the life of your wood finishing investment, ensuring enduring beauty and resilience.

Expert Techniques and Pro Tips for Flawless Results

Achieving a flawless wood finishing result in 2026 requires more than just quality products. It demands a blend of advanced techniques, problem-solving skills, efficient workflows, and a commitment to sustainability. Whether you are a DIY enthusiast or a seasoned professional, mastering these expert strategies will elevate your work and ensure results that stand the test of time.

Advanced Application Methods

Modern wood finishing calls for precision and innovation. High-Volume Low-Pressure (HVLP) sprayers and airless sprayers have become essential for achieving smooth, even coats with minimal overspray. These tools deliver professional-level results, especially on large surfaces or intricate furniture.

Traditional methods still hold value. French polishing, which uses shellac and a rubbing pad, creates a deep, lustrous finish ideal for heirloom pieces. Hand-rubbed oil techniques, such as applying tung or Danish oil with a lint-free cloth, enhance the natural character of hardwoods.

Layering stains and glazes allows for custom effects. For example, a cerused oak finish is created by brushing liming wax into open grain, then buffing for a textured, whitewashed look. Mastering these techniques can be challenging, but resources like Woodworking blogs and guides provide in-depth tutorials and insider tips for all skill levels.

Experimenting with new tools and methods is key to staying ahead in wood finishing.

Troubleshooting Common Problems

Even experts encounter issues during wood finishing projects. Blotchy stains, drips, runs, and fisheyes can mar an otherwise perfect piece. Dust nibs and bubbles often result from airborne particles or improper application. Orange peel texture, caused by incorrect spray technique or viscosity, is another frequent challenge.

Addressing uneven sheen and color requires patience. Lightly sanding between coats with fine grit, then reapplying finish, can often resolve inconsistencies. Using a clean, controlled workspace and maintaining optimal humidity and temperature help prevent many common flaws.

A recent study found that 40% of DIYers encounter at least one finish flaw per project. Keeping spare materials for spot repairs and practicing on scrap wood can significantly reduce frustration. Staying informed about the latest wood finishing techniques will help you avoid costly mistakes.

Time-Saving Tips and Efficiency Hacks

Efficiency is essential for both professionals and serious hobbyists. Fast-drying products, such as advanced waterborne finishes, allow for multiple coats in a single day. Batch processing, where several pieces are finished simultaneously, improves workflow and consistency.

Setting up an assembly-line process, with dedicated zones for sanding, staining, and topcoating, minimizes downtime. Digital timers ensure precise curing, while smart sensors monitor air quality and drying conditions in real time.

Utilizing microfiber applicators, HVLP sprayers, and vacuum dust collection systems accelerates production without compromising quality. Incorporating these time-saving strategies into your wood finishing routine streamlines projects and delivers professional results.

Sustainable and Eco-Friendly Finishing Practices

Sustainability is a growing priority in wood finishing for 2026. Choosing low-VOC, plant-based, and biodegradable finishes protects both the environment and indoor air quality. Many leading brands now offer waterborne polyurethane with up to 80% lower emissions compared to traditional varnishes.

Waste reduction is also vital. Reusable applicators, careful mixing to avoid excess, and responsible disposal of solvents contribute to greener workshops. Selecting finishing products certified for low emissions ensures compliance with tightening regulations in North America and Europe.

Adopting eco-friendly practices not only benefits your health but also meets the expectations of environmentally conscious clients. Making sustainable choices in wood finishing is both responsible and forward-thinking.

Choosing the Right Products and Tools: 2026 Recommendations

Selecting the right products and tools is the cornerstone of a successful wood finishing project. With evolving technology and growing environmental awareness, 2026 offers a range of options tailored for both professionals and DIYers. The right choices not only impact the look and longevity of your work but also ensure safety and efficiency at every step.

Best Wood Finishing Products for Different Needs

Choosing the appropriate wood finishing product is essential for achieving both durability and the desired aesthetic. In 2026, eco-friendly innovations are at the forefront, with water-based and bio-based finishes gaining popularity for their low emissions and easy cleanup. Many professionals and hobbyists alike are turning to top-rated stains, sealers, and topcoats that balance performance with safety.

For those seeking inspiration or product ideas, curated wood finishing collections and trends can help you discover the latest finishes and application styles. Whether you need a high-build polyurethane for heavy traffic areas or a plant-based oil for natural beauty, there is a solution for every project.

Here’s a snapshot of leading product types for 2026:

| Product Type | Example Brands | Eco-Friendly | Application | Typical Cost |

|---|---|---|---|---|

| Water-based Polyurethane | Bona, General Finishes | Yes | Brush/Spray | $$ |

| Plant-based Oil | Rubio Monocoat | Yes | Wipe/Rag | $$$ |

| Low-VOC Lacquer | Target Coatings | Yes | Spray | $$ |

| Gel Stain | Varathane, Minwax | Some | Wipe/Brush | $ |

Selecting the right wood finishing product ensures your furniture stands out, resists wear, and aligns with current trends.

Essential Tools and Accessories

Having the right tools is just as important as selecting a quality wood finishing product. In 2026, HVLP sprayers are used by over 90% of professionals for large projects, thanks to their efficiency and fine atomization. Microfiber applicators and premium brushes ensure smooth, streak-free finishes on all surfaces.

Smart workshop gadgets are making a significant impact. Digital moisture meters help verify wood readiness, while air quality monitors and smart sensors provide real-time feedback to maintain safe environments. Safety gear, including respirators and gloves, remains non-negotiable for both professionals and hobbyists.

For a comprehensive overview of must-have equipment, the Essential woodworking tools overview offers detailed guides and safety tips. Investing in the right accessories not only streamlines the wood finishing process but also boosts accuracy and consistency.

Where to Buy and What to Look For

Finding reputable suppliers is crucial when sourcing wood finishing products and tools. Look for retailers that offer certified, low-emission finishes and provide transparent product information. Many professionals prefer buying from specialized woodworking stores or trusted online platforms to ensure authenticity and quality.

When evaluating products, check for certifications that verify low VOC content or sustainable sourcing. Reading user reviews and seeking recommendations from woodworking communities can also help you avoid counterfeit or subpar options. Comparing warranties and return policies further safeguards your investment.

Staying informed about the latest innovations and standards empowers you to select wood finishing products and tools that meet your needs, budget, and values. Proper sourcing is the final step in achieving professional, lasting results.

Wood Finishing for DIYers vs. Professionals: Skills, Courses, and Resources

Mastering wood finishing requires more than just the right products or tools. Whether you are a hobbyist or a seasoned professional, understanding the differences in skill levels, educational resources, and support networks is crucial for success. In 2026, the landscape of wood finishing education and community support is more dynamic and accessible than ever.

Skill Levels and Learning Paths

The difference between DIY and professional wood finishing often comes down to experience, technique, and access to specialized knowledge. DIYers may start with small projects, focusing on learning the basics of preparation, staining, and topcoating. Professionals, on the other hand, rely on advanced methods, industry best practices, and years of hands-on work.

Hands-on practice is essential at every stage. Many beginners find that guided instruction accelerates their progress. According to industry surveys, 65% of newcomers report significantly better wood finishing results after completing a structured training course.

To bridge the skill gap, consider starting with simple projects and gradually introducing more complex finishes. This approach builds confidence and ensures each new wood finishing challenge becomes an opportunity for growth.

Online Courses, Tutorials, and Certification Options

In 2026, online learning platforms and certification programs make wood finishing education accessible worldwide. Top-rated courses offer step-by-step video tutorials, interactive lessons, and live feedback from professionals.

Popular learning resources include:

| Platform | Focus Area | Certification Offered |

|---|---|---|

| Woodworking Academy | Comprehensive wood finishing | Yes |

| YouTube Channels | Project demos, pro tips | No |

| Skillshare/Udemy | Specialty techniques | Sometimes |

Video tutorials and interactive classes help learners visualize processes and avoid common mistakes. Certification programs add credibility and open doors to professional opportunities. Many wood finishing experts recommend following respected YouTube educators or enrolling in online academies for the most up-to-date techniques.

Community, Support, and Inspiration

A supportive community can be invaluable for troubleshooting wood finishing challenges, sharing ideas, and finding inspiration. Forums and social media groups host discussions on everything from stain selection to advanced finishing effects.

Participating in maker communities connects you with both beginners and seasoned professionals. Many platforms host annual online wood finishing competitions, where participants showcase their best work and share detailed project galleries.

These events not only celebrate craftsmanship but also foster motivation and continuous improvement. Whether you are seeking advice or sharing progress, community engagement makes the wood finishing journey richer and more rewarding.

Staying Updated with Trends and Techniques

The world of wood finishing evolves rapidly, with new products, styles, and regulations emerging each year. Staying current means subscribing to trade magazines, industry blogs, and newsletters. Many professionals attend virtual workshops and trade shows to learn about the latest innovations.

In 2025, there was a 30% increase in online woodworking course enrollments, reflecting a growing interest in advanced wood finishing skills. For those interested in trending colors and techniques, resources like the 2026 Stain of the Year provide insights on popular finishes and their applications.

Regularly updating your knowledge ensures that your wood finishing projects remain fresh, durable, and in line with modern design expectations.

As you explore the latest techniques, product recommendations, and expert insights from our wood finishing guide, you might be inspired to take your furniture projects to the next level. Whether you’re a seasoned woodworker or just starting out, having access to high-quality 3D CAD models can streamline your design process and help you visualize stunning, professional results before you even pick up a brush. If you’re ready to experiment with new forms or want to expand your creative toolkit, you can learn how to create furniture designs with premade 3D cad and bring your ideas to life with confidence.

Share:

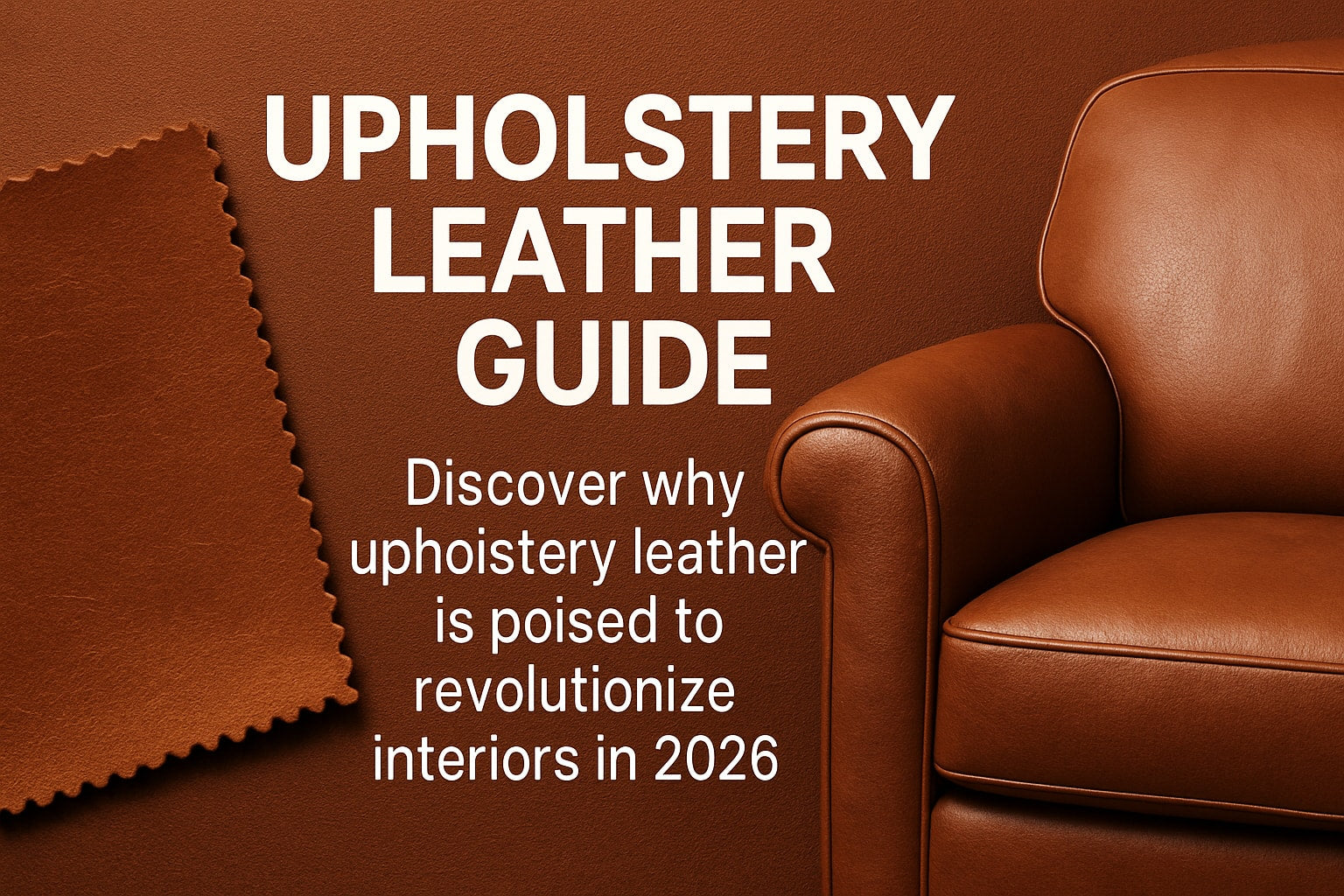

Sustainable Wood Guide: Your Eco-Friendly Resource for 2026